Gears

Overview

- What they are:

- Wheels with teeth cut around their edges.

- What they do:

- The teeth of one gear fit into the teeth of another gear, so turning one gear makes the connected gear turn. They are used to transfer power and can change how fast something spins or the amount of twisting force (torque), and even change the direction.

- Pros:

- Very strong and efficient for transferring power, highly precise motion (no slipping), good for changing speed and torque in a small space.

- Cons:

-Can be loud, need to be lined up very carefully to work right, only work well when they are close together, can cost more to make.

Argos Standard

Gears

Argos almost always uses 20dp gears with hex shafts or spline shafts.

- 20dp refers to the specific size and spacing of the gear teeth, ensuring proper meshing.

- Hex shafts are the six-sided axles these gears mount onto, providing a strong, non-slip connection

- Spline shaft is a rod that has multiple ridges or "teeth" running along its length.

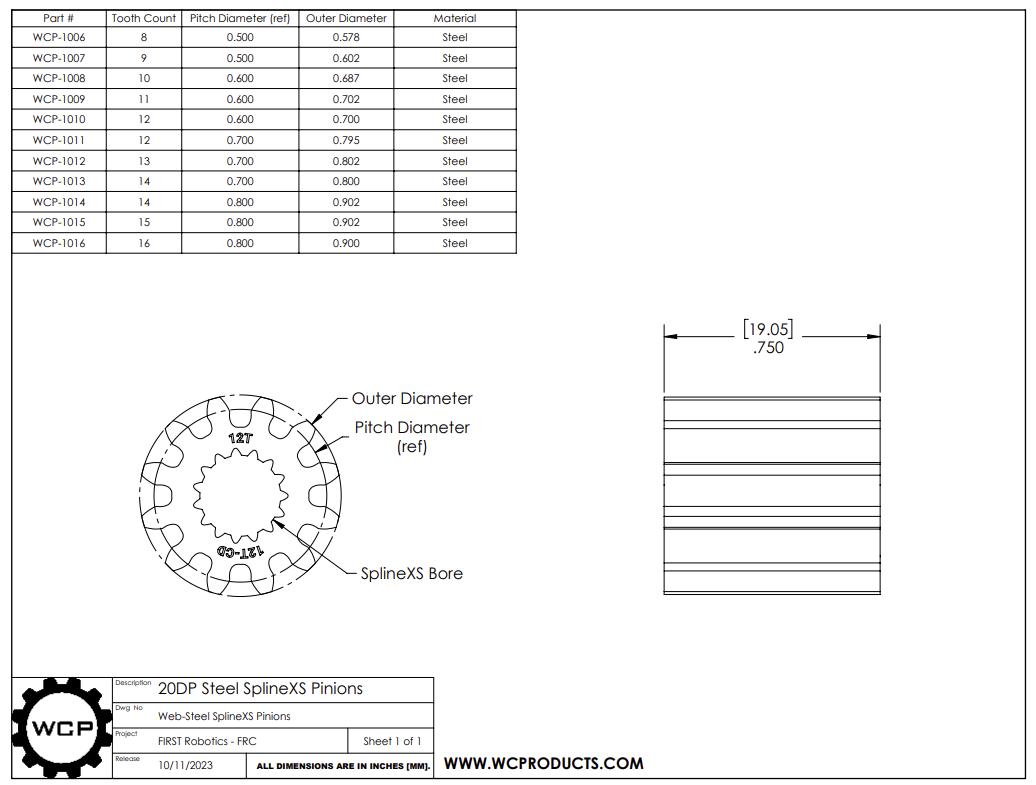

Pinions

A pinion is just a small gear. It's often the first gear connected to a motor or spinning shaft, and it meshes with a larger gear to transfer power.

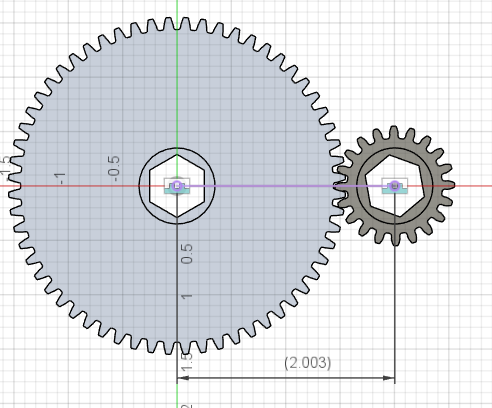

How to Calculate Gear Center Distance

Gear Center Distance Calculator

To calculate the theoretical center distance between two meshing spur gears with the same diametral pitch (DP), you use the following equation:

Center Distance = ((N1+N2)/(2 x DP)) + Extra_Distance

Where:

- N1 is the number of teeth on the first gear

- N2 is the number of teeth on the second gear

- DP is the diametral pitch (the number of teeth per inch of pitch diameter)

- Extra_Distance = account for manufacturing tolerances and ensure smooth operation (Should be 0.003 in)

Gear Calculator

Gear Center Distance Calculator

Motor Performance Calculator

Motor Performance Calculator

Step 1: Select Motor

Step 2: Input Gear Ratio

• Ratio = 1 (direct drive)

• Ratio = 10 (10:1 reduction)

• Ratio = 0.5 (2:1 speed increase)

Step 3: Output Type

Step 4: Geared Performance

Quick Reference

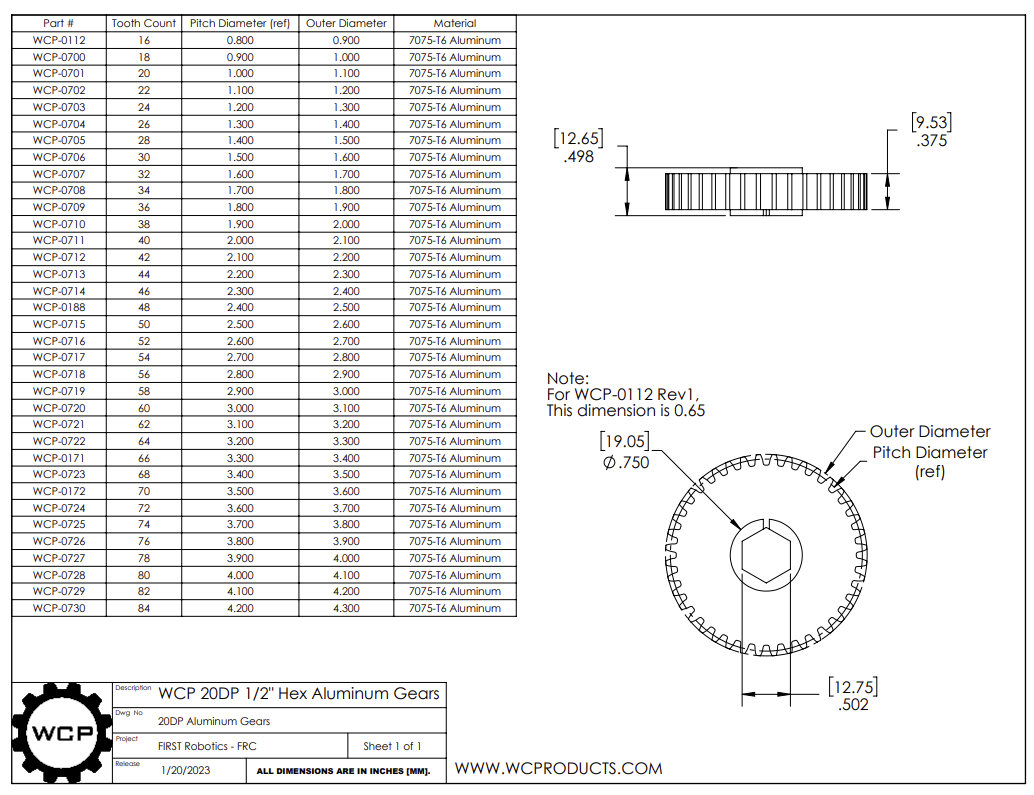

1/2" Hex Gears

Stocked Sizes

Available teeth: 20 | 30 | 40 | 50 | 60

Where to Buy

1/2 Hex Gears - West Coast Products

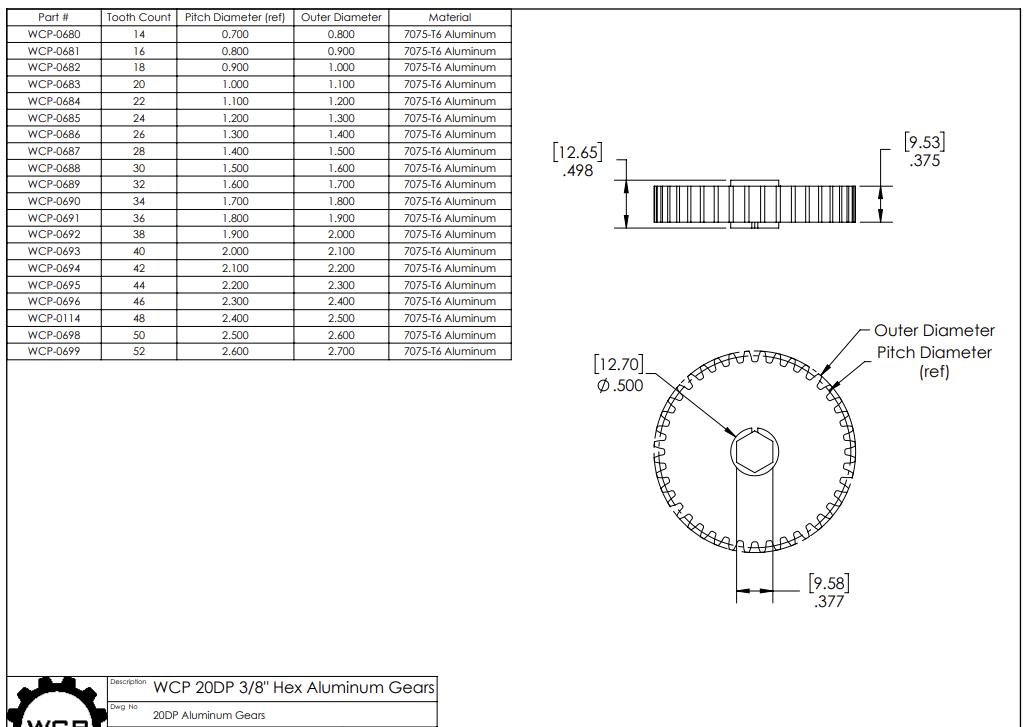

3/8" Hex Gears

Stocked Sizes

Available teeth: N/A

Where to Buy

3/8 Hex Gears - West Coast Products

Falcon Pinion

Stocked Sizes

Available teeth: 12 | 14 | 16

Where to Buy

Falcon Pinions - West Coast Products

Kraken Pinion

Stocked Sizes

Available teeth: 12 | 14 | 16

Where to Buy

Kraken Pinions - West Coast Products